Steel fabrication is an intricate and transformative process in the world of construction and manufacturing. It involves transforming raw steel into usable products or structural elements. This process isn’t just about altering the physical state of steel; it’s about engineering the steel to meet precise specifications for construction projects and industrial fabrication applications. The versatility and strength of steel make it a valuable material across various industries.

Steel Fabrication’s Role in Diverse Industries

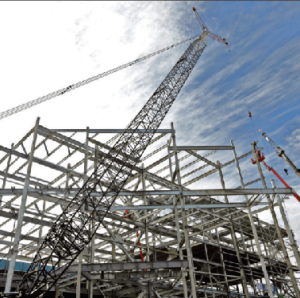

The importance of steel and metal fabrication is seen in numerous sectors, including construction, automotive, data centers, aviation, and more. In construction, it provides the backbone for buildings, bridges, and long-lasting structures, offering unmatched durability and support. In the automotive industry, steel fabrication is used for creating strong and lightweight vehicle frames that ensure safety and efficiency. Several industries rely on steel fabrication for building structures that are capable of withstanding extreme conditions. Each industry requires steel to be fabricated in unique ways, demonstrating its excellent adaptability.

In the steel fabrication industry, Superior Rigging & Erecting Co. stands out for our expertise and excellence. We aren’t just experts in fabricating; we craft unique solutions to cater to any construction project. In this blog post, we will dive into the steel fabrication process, explore the types of steel used, and highlight the importance of skilled fabricators and quality control in this field.

The Steel Fabrication Process

As mentioned above, the steel fabrication process is a transformation of raw steel into a final product that serves specific functions. The entire process begins with the selection of the highest quality steel, the backbone of the fabrication process. The steel, available in various forms like beams, sheets, channels, tubes, or rods, undergoes a series of meticulous processes to shape it into the desired final form.

Key Steps in the Steel Fabrication Process

Steel fabrication is an intricate process that requires attention to detail at every stage. From the initial cutting of the material to the finishing and inspection, each step plays an important role. Here, we outline the steps involved in transforming raw materials into a usable, quality product:

- Cutting: The first step involves cutting the steel into the desired shape and size. This is achieved with a variety of tools and techniques, such as laser cutting, plasma cutting, or traditional mechanical processes. Each method has its advantages and is chosen based on several factors: the thickness of the metal, the cutting speed, and the type of cut required.

- Forming: After cutting the steel, it’s shaped into its desired form. This involves bending or stretching the steel using press brakes or other machinery. Forming the metal into its shape is a critical step for assembling the steel components into the final product.

- Assembling and Welding: The next phase involves assembling the metal parts. Steel fabricators use various techniques like welding, riveting, or bolting to join different pieces together. The precision in this step is important for creating the desired shape and determining the product’s structural integrity.

- Finishing: Once assembled, the steel structure often undergoes finishing processes where the steel is cleaned, possibly sandblasted, painted, or even galvanized. This enhances the aesthetic appeal of the product but also provides a protective layer for increased durability and corrosion resistance.

- Inspection and Quality Checks: Throughout the fabrication process, rigorous inspections and quality checks are conducted. This ensures that the steel products meet all required specifications and standards.

Modern Technology in Steel Fabrication

The steel fabrication process is a blend of advanced technology, extensive experience, and talented metal fabricators and welders. The use of modern technology enhances the efficiency, accuracy, and safety of the overall process. Modern advancements and automated machinery allow for precise planning, ensuring each piece of sheet metal is fabricated to exact specifications. This machinery has revolutionized traditional methods, crafting consistent and accurate cuts while increasing productivity.

Advanced technology has also improved the environmental footprint of steel fabrication. Modern machinery is more energy-efficient and reduces waste by optimizing the use of materials. This advancement contributes to more sustainable manufacturing practices, opening up new possibilities in construction.

In this detailed guide to the steel fabrication process, there is a perfect blend of skilled craftsmanship and technological innovation. Each step, from choosing the right materials to the final inspection, plays a role in shaping the quality of the final steel product.

Types of Steel Used in Fabrication

With steel fabrication, the type of steel chosen is as important as the fabrication process. Different types of steel have their own unique properties, and they offer versatility in structural and aesthetic components. It’s important to create structural steel components and materials that meet various industry needs.

SRE’s steel fabrication shop produces miscellaneous steel, such as steel columns, beams, trusses, girders, joists, and decking. With a commitment to quality and durability, we also produce smaller iron, stainless steel, and aluminum items if required.

Additional types of steel common in fabrication include plate metal and flat metal. Plate metal is a thick and strong material used in heavy-duty projects where durability is more important than saving weight. On the other hand, flat metal is a metal that’s easy to shape into thin, flat pieces. The importance of steel type is demonstrated in each individual construction project, ensuring durability and high quality.

Choosing the right type of steel and shape is crucial in ensuring the structural integrity and functionality of the final metal product. This decision impacts the ease of fabrication and the long-term durability and performance of the steel components.

The Role of Skilled Fabricators and Quality Control

A skilled team of fabricators is a crucial aspect of the steel fabrication process. These professionals apply their expertise in the industries of structural steel, miscellaneous steel, millwrighting, and rigging. This expertise encompasses an understanding of various steel types, precision in cutting techniques, and proficiency in welding and assembling processes.

Precision and Skill in Fabrication

The precision in steel fabrication lies in the technology but also in the hands of the fabricators who operate it. These individuals work with cutting-edge machinery, ensuring each cut, bend, and weld is executed with accuracy. A talented team of American Welding Society Certified Welders employs the best techniques and solutions for every construction project, ensuring they are completed at the highest standards of quality and performance.

Quality control is another important aspect of the metal fabrication process. It involves rigorous machinery checks and inspections at every stage of fabrication. Our skilled technicians ensure that every piece of fabricated steel adheres to the project’s standards and specifications. This process ensures the safety, durability, and optimal performance of the steel products, establishing confidence in their use in various applications.

SRE: The Premium Steel Fabrication Company

As we’ve learned, steel fabrication involves transforming raw steel into functional, durable products. It’s a manufacturing process that requires precision, expertise, and an understanding of the construction materials used. From the initial steps of cutting and forming to assembling and finishing, each phase is crucial in shaping the finished product. This process supports various industries and contributes to our daily lives, from the buildings in which we live to the vehicles we use.

Superior Rigging & Erecting Co. stands as a leader in the metal fabrication industry. With our extensive experience and commitment to quality, we deliver unparalleled services and innovative solutions in fabrication. Our use of cutting-edge technology, combined with our team of skilled fabricators, ensures that every project is completed with professionalism. Whether it’s for structural steel or custom metal, we meet the unique needs of our clients, offering effective and reliable solutions.

We invite you to experience the exceptional service and quality that Superior Rigging and Erecting Co. offers. No matter how complex your project is, we are ready to bring your vision to life with our comprehensive steel fabrication services. You can trust us to be your partner in designing and crafting structures that last a lifetime. Contact SRE today to discover how we contribute to the success of your project with our top-quality steel fabrication services.

Resources:

- American Welding Society Certified Welders. https://www.aws.org/home

- Superior Rigging & Erecting Co. https://superiorrigging.com/