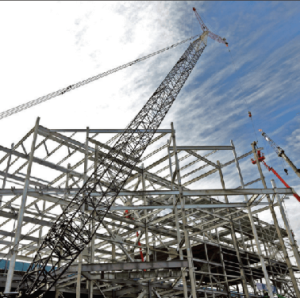

The construction industry is one of the most dangerous in the world and given the heights that are involved in rigging operations, safety training for rigging equipment is vital to prevent injuries for your crew. However, construction isn’t the only industry that can benefit from rigging safety protocols, which help protect your people from a worn wire rope, defective sling, or a crane operator that hasn’t been certified.

With June being National Safety Month, we felt it was appropriate to cover some job site practices to help you ensure your employees and contractors stay safe. In this article, we’ll look at why rigging safety is important, the basics to get your crew operating rigging safely, regulations and standards that are used with rigging safety, best practices to improve rigging operation and safety, and how modern technology can help your crew incorporate a better safety factor into their construction site operations. Though this will give you the basics, it’s not a substitute for a professional course or additional training.

The Importance of Rigging Safety

Rigging safety incorporates a number of different factors that can impact your worksite safety. Material handling, fall protection, lifting operations, regular inspections of hoisting equipment, hand signal training, work practices and a proper safety culture in your organization can make a big difference in protecting your workers from a serious injury.

According to studies by the Centers for Disease Control, 24 out of 40 crane-related fatalities happened because of rigging failure. That’s 60%, a huge improvement is possible if a competent person notices that a synthetic web sling is worn, periodic inspection isn’t forgotten, or safety standards are not ignored. The Bureau of Labor Statistics notes a similar statistic of 60% out of 42 fatalities who were struck by something that fell due to a failed rigging.

By treating rigging as something that can be dangerous instead of just another piece of equipment, you can help prevent rigging accidents on your construction site. By setting up protocols and standards for rigging operations, you can ensure that you have fewer workplace injuries and protect your workers from dangerous accidents.

The Basics of Rigging Safety

Rigging safety is everyone’s responsibility on the job site. From checking that you’ve got the right load weight for a crane or wire rope to regular inspection of your lifting equipment, these details help save lives. There are four primary aspects of rigging safety:

Correct use of equipment

The only way you should use your lifting equipment is the right way with safe rigging. Make sure your crew is familiar with the consequences of shock loading, where the load is suddenly increased, shifted, or decreased, causing the wire rope to either strain or recoil. Make sure that proper rigging techniques and hardware are used to avoid accidents. Only use rigging hardware that is approved for that purpose, and only use rigging practices that each piece of equipment is approved for to prevent accidents.

Regular inspection and maintenance

Regular inspection and maintenance of your equipment is vital. If using synthetic fiber rope slings, alloy steel chain slings, or wire rope slings, take the time to inspect them prior to use to make sure there is no wear or damage that could cause a failure. If a piece of equipment has a paint frame that is chipping or peeling, repaint it to prevent weakness due to corrosion. Create a regular inspection and maintenance schedule for your equipment so that it is checked regularly, and check equipment that has been in storage for a while before using it.

Training and certification

Whether it’s an online course, an on-site apprenticeship, or an in-person class, making sure that your crane operators and riggers are up to date on their qualifications means that they’re staying updated on the latest changes in the industry. This can include things such as new issues with a previously approved lifting technique. Make sure that you see each individual’s certification rather than taking their word on the matter, because finding out they weren’t a qualified rigger after the fact won’t undo the damage.

Proper planning and risk assessment

Among the most important documents on your construction site is your lift plan. Whenever you need to make a lift with a crane, the lift plan for that material, load limit, or similar factor should be reviewed to ensure that everyone understands what’s going on. Once you’ve verified the plan, walk through the process with your personnel, ensuring that they’re using the proper hand signals for specific actions. By taking a few extra minutes in the job site office, you can ensure that everyone goes home that evening.

Rigging Safety Regulations and Standards

In the United States, the Occupational Safety and Health Administration, or OSHA, provides crane, rigging, and lifting regulations to promote job site safety. Though it would take a much longer article to cover every aspect of OSHA regulations, here’s a quick overview of the standards and regulations that OSHA requires:

- Cranes and rigging equipment shall be inspected before a shift and as many times during a shift as is necessary.

- Equipment must have legible and permanently attached load markings and it shall not be loaded above that upper range.

- When not used, rigging equipment shall be removed from the work location.

- Suspended load routes will be pre-planned to keep employees out from under the load.

Though it can be tempting to skirt these safety regulations, that can leave your business with a big fine on the other end of a surprise OSHA inspection or after an accident on the construction site. These regulations and standards have been developed after years of dedicated study of crane and rigging accidents to prevent more accidents in the future. By taking the time to stay in compliance with OSHA and similar regulations on your construction site, you can make sure that your crew can work safely.

Best Practices for Enhancing Rigging Safety

There are a range of best practices that you can incorporate into your company’s policies and procedures to ensure that your rigging team stays safe and is able to prevent many accidents on the job site. However, there are four that are the most important when trying to improve rigging safety:

- Use appropriate protective gear: From hard hats to safety harnesses, personal protective equipment can save your crew a lot of grief, but when it comes to lifting, this should also include the type of sling you’re using for a particular type of lift, checking eye splices, and similar approaches.

- Adhere to load limits: Whatever the weakest link of your lifting equipment is rated should be the heaviest load that you lift. If you’re moving a 5-ton air conditioning unit, don’t use a 4-ton sling and hope it will be okay. This applies to your crane, rigging, wire rope, and attachment equipment.

- Implement a strong communication system among the rigging team: Radios and cell phones may be common ways of communicating, but on a loud job site, hand signals and flags may do more to improve worksite safety. Make sure that any communication form has backups.

- Create a culture of safety: More than anything else, building a culture of safety in your business will save lives. Make sure that any member of the crew, no matter their seniority or position, has the right to speak up if they feel a situation isn’t safe. Reward your crews for length of time without accidents.

The Role of Technology in Rigging Safety

There are a great many examples of how modern technology can improve your rigging safety. These can include up-to-the-moment weather reports to prevent wind-driven accidents, drones for inspecting rigging connections in dangerous locations, engineered systems to optimize synchronized lifting to prevent accidents from shock loading, and GPS to provide exacting locations for both the crane operator and load, allowing them to use the best possible location for lifting the load.

In addition to these current technologies, some options that may be watched for in the future can include self-driving cranes that help prevent injuries to a crane operator in dangerous circumstances, automated synchronized lifting systems that communicate and handle the lift by machine control, automated lift control to prevent human error, and similar aspects of rigging safety that can ensure that workplace injuries from cranes and rigging are further reduced.

Crane and Rigging Safety from Superior Rigging

Crane and rigging safety is of vital importance to the job site, keeping workers safe in what can often be a difficult environment. By following the safety recommendations above and making sure to stay in touch with changes in the industry, you can be sure that your crew can remain safe while on the construction site.

With a strong dedication to safety, Superior Rigging and Erecting Co. is focused on helping your crew work more safely around rigging and cranes. From offering experienced operators to rigging expertise to make sure that you can get your load where it needs to go safely, you’ll find out why we’re called the rigging company with a gentle touch. If you’re ready to make your next lift, we can provide you with the right rental crane, a qualified crane operator, and advice on how to move that difficult load to avoid job site accidents. Please feel free to reach out today with any questions, for more details, or to get a quote on our rentals and services.