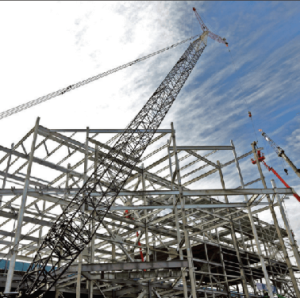

If you’ve ever marveled at the sight of a towering skyscraper or a sprawling industrial complex, you’ve witnessed the result of the complex process known as structural steel erection. This process, which is central to the construction of multi-story buildings and structures, involves the assembly of steel framework, providing a skeleton upon which the entire building stands.

Structural steel erection is more than simply putting pieces together; it’s an intricate ballet of precision, engineering, and coordination. A successful steel erection process gives life to architectural drawings, transforming them into tangible structures that dominate our urban landscape.

Why Steel?

Steel, being a versatile and robust material, plays an essential role in the structural integrity of modern buildings. From hospitals and schools to bridges and skyscrapers, structural steel contributes significantly to our built environment. The use of steel in construction projects offers numerous benefits, such as strength, durability, and flexibility, making it a go-to choice for developers and architects worldwide.

Furthermore, steel construction allows for the efficient and quick erection of buildings. The process of structural steel erection involves aligning and securing steel components into a predetermined structural design, enabling the creation of incredibly tall structures. This is evident in the skyline of every major city, filled with towering steel structures.

Structural steel erection is an essential facet of the steel construction industry, responsible for the creation of robust and high-rise steel structures. As we move forward, it is interesting to observe how this process evolves and innovates to meet the changing needs of architecture and construction. Thus, understanding the basics of structural steel erection is not only crucial for those involved in the industry but also for anyone interested in the fascinating world of construction and design.

In the sections that follow, we will delve into the process of steel erection, discuss safety aspects, explore recent industry innovations, and highlight the contributions of a leading company in the field, Superior Rigging & Erecting Co. By the end of this blog post, you’ll have a comprehensive understanding of what structural steel erection entails, its importance, and its role in the broader construction industry.

The Process of Steel Erection

Steel erection may seem straightforward at a glance – after all, isn’t it just assembling parts? But it is far from simple. It’s a process that requires exceptional skills, precision, and a profound understanding of both materials and engineering principles. Let’s delve into the process of steel erection to understand it better.

Planning and Design

Before any physical work begins on a construction site, the erection process starts with the development of a detailed, site-specific erection plan. This plan outlines the sequence of operations and provides guidelines on safely erecting the structure, ensuring structural stability throughout the project.

An integral part of the planning phase involves the creation of erection drawings. These drawings are detailed blueprints for the ironworkers, indicating where each steel beam, joist, and structural member fits into the overall structure. Accurate erection drawings are critical in ensuring the correct assembly of the steel structure.

Preparation and Delivery

Once the plans are in place, the next step involves the delivery of structural elements to the construction site. This includes steel beams, structural iron, and other structural members. Each piece is typically prepared off-site and brought to the construction site when needed, according to the site-specific erection plan.

Erection Process

At the heart of the erection process are the ironworkers. These skilled professionals, often assisted by crane operators, are responsible for aligning and securing the structural members according to the erection drawings.

The ironworkers assemble the steel structure piece by piece, usually beginning with setting the structural columns in place and tying the steel beams to these for a stable structure. This work requires great precision, as each beam needs to be aligned correctly to ensure the structural stability of the entire building.

Finishing the Structure

Once all the structural members are in place, the ironworkers finalize the structure by bolting or welding the components together. This step gives the structure sufficient strength and prepares it for the installation of additional elements such as metal decking and steel studs.

Understanding the process of structural steel erection provides an insight into the complexities of this essential construction task. With each step carefully planned and executed, the result is a steel structure that stands strong, ready to serve its purpose for decades to come. In the next section, we will look at some of the safety aspects and challenges in steel erection.

Safety and Challenges in Steel Erection

Structural steel erection, while a marvel of engineering, is not without its challenges. It requires careful planning and execution to ensure not just the successful construction of the building, but also the safety of everyone involved in the project. Let’s delve into the safety measures and challenges encountered in steel erection.

Ensuring Structural Stability

One of the biggest challenges in steel erection is ensuring the structural stability of the steel frame during the erection process. The temporary structure must have sufficient strength to support itself and resist external forces like wind loads.

Shear connectors, which help achieve composite action between the steel beams and concrete slabs, play a crucial role in improving the structural stability of the steel frame. In addition, diagonal erection bridging and plumbing-up equipment are often used to stabilize the structure during the erection process.

Safety Measures in Steel Erection

Safety is always a top priority in any construction project, and steel erection is no different. Ironworkers must follow strict safety protocols to prevent accidents on the construction site. This includes wearing appropriate personal protective equipment and using fall protection systems when working at height.

A crucial part of safety in steel erection involves the creation and implementation of a comprehensive safety plan, which outlines safety protocols for various stages of the erection process. Regular safety inspections and audits also help ensure that these measures are being correctly implemented.

Addressing the Challenges of Steel Erection

Despite meticulous planning and stringent safety measures, steel erection can still pose challenges. Weather conditions, for example, can cause delays and affect the safety of the erection process. Site constraints, such as limited space for the storage of materials and machinery, can also make the erection process more complex.

Nevertheless, experienced ironworkers and construction teams can navigate these challenges with effective problem-solving and adaptability. After all, the successful completion of a steel structure not only requires technical skills but also a deep understanding of the unique circumstances of each construction project.

As we delve deeper into the world of steel erection, it becomes evident how this complex process relies heavily on planning, precision, and safety measures. In the next section, we will discuss the advancements and trends that are shaping the future of the steel erection industry.

Innovations and Trends in the Steel Erection Industry

Just like every other industry, the field of structural steel erection is constantly evolving. Innovations and advancements in technology have paved the way for more efficient and safer erection processes. Let’s explore some of these cutting-edge trends reshaping the landscape of the steel erection industry.

Emergence of Pre-engineered Metal Buildings

One of the most significant trends in the industry is the emergence of pre-engineered metal buildings. These structures are designed and fabricated off-site, allowing for a faster and more efficient erection process on the construction site. The components are prefabricated according to a specific design and can be quickly assembled, drastically reducing the construction time.

Technological Innovations in Steel Framing

Technology has also made significant strides in the steel erection industry. Advanced tools and software are now available to aid in the design and planning stages of steel erection, helping to create more accurate erection drawings and site-specific erection plans.

Moreover, technological advancements have also been made in the field of steel framing. Modern steel framing systems have made the erection process more efficient, allowing ironworkers to complete their tasks faster and with greater precision.

Role of Steel Erection Contractors and General Contractors

The roles of steel erection subcontractors and general contractors are evolving with the changes in the industry. As the industry embraces new technologies and methods, contractors are required to keep up with these advancements. They are investing in training their teams on the latest trends and technologies, ensuring they can deliver the most efficient and high-quality services to their clients.

The steel erection industry is clearly in a state of constant evolution, with technology and innovative construction methods leading the charge. The industry’s future looks promising, with continued advancements expected to improve efficiency, safety, and the overall quality of steel construction.

Now, let’s turn our attention to Superior Rigging & Erecting Co., a company that has been at the forefront of the steel erection industry, embodying these trends and setting a high standard for steel erection projects.

Superior Rigging & Erecting Co.: Pioneering the Future of Structural Steel Erection

In the realm of structural steel erection, Superior Rigging & Erecting Co. stands as a testament to seven decades of unyielding dedication and outstanding craftsmanship. Founded in 1952, we have become a trusted partner for a multitude of services, including steel erection, crane rentals, rigging, architectural precast, and more.

Our expertise in navigating complex steel projects all across the United States, coupled with our unwavering commitment to delivering excellence, sets us apart in the industry.

The Cornerstones of Superior Rigging & Erecting Co.: Experience, Expertise, Adaptability, and Trust

Our reputation in the structural steel erection arena has been built upon four fundamental principles: Experience, Expertise, Adaptability, and Trust.

Experience – Our experience, spanning over 70 years, empowers us to tackle even the most intricate projects. From erecting low-rise steel structures to relocating heavy machinery, we handle a wide range of complexities with proficiency.

Expertise – At Superior Rigging & Erecting Co., we pride ourselves on our highly skilled team of ironworkers and crane operators. Our in-depth understanding of the erection process, from precision in erection drawings to ensuring structural strength during the erection process, is the key to our successful projects.

Adaptability – Our ability to adapt to the evolving landscape of the industry is a defining characteristic. As industry dynamics shift, we shift with them, integrating new technologies and methodologies to meet the needs of our clients and their diverse projects.

Trust – We have won the trust of our clients through consistent delivery of quality services. Safety, reliability, and professionalism are the keystones of our operations, making us a reliable partner for any steel erection project.

The Journey Ahead with SRE

As we look towards the future, Superior Rigging & Erecting Co. is geared to continue driving innovation in the steel erection industry. Our unwavering commitment to adopting industry advancements and upholding the highest safety standards allows us to consistently deliver extraordinary outcomes.

Interested in our steel erection services? Request a quote today.