A professional millwright is a highly skilled individual who plays a role in the installation, maintenance, and repair of heavy machinery and equipment. Industrial millwright work is the core of operational efficiency in various industries, including power plants, construction, and manufacturing. These workers make sure the backbone of infrastructure and manufacturing capabilities remain strong and efficient.

As industries continue to evolve and expand, the demand for skilled millwright services becomes critical. Whether installing a new production line, performing routine maintenance, or responding to emergencies that require immediate attention, millwrights play an important role in keeping the wheels of the industry turning.

Roles and Responsibilities

A millwright is a skilled tradesperson who handles machinery installation, repairs, and reassembles machinery in factories, plants, and on construction sites. This ensures the longevity and performance of the machinery and the safety of the entire operation. Millwrights are tasked with the job of keeping machinery in optimal operating condition, which prevents costly downtime and ensures continuous productivity.

Their expertise is not limited to maintenance; millwrights work in many industrial settings where they dismantle and relocate entire plants. This skill is valuable when industries expand or move their operations, which requires a seamless transition with minimal impact on production.

Skills and Qualifications

A millwright’s skill set is earned through rigorous training and hands-on experience. This includes an understanding of mechanical equipment, precision in the installation and repair processes, and a commitment to adhering to safety procedures on construction sites. Their work requires a high level of precision and technical knowledge because these individuals install intricate machinery and troubleshoot issues that arise.

Day to Day Operations

The daily routine of a millwright is complex. One day may involve installing conveyors in a newly constructed mill, while another could be performing emergency repairs for a critical construction project. This versatility and ability to address various technical challenges are what make millwrights valuable to the smooth operation of a project. Although millwrights typically work in the background, their impact is always at the forefront of operational efficiency and success.

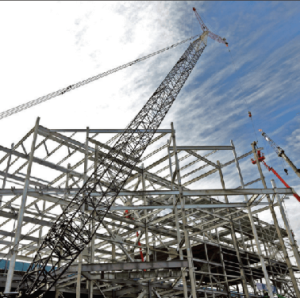

The Critical Role of Millwrights in Construction Projects

Millwright jobs are often demanding and have an important role in making sure a project is completed without interruption. The construction sector relies heavily on the smooth operation of heavy industrial machinery and equipment. From the initial groundbreaking to the final touches, machinery must operate at its best. Millwrights use their knowledge to prevent the costly delays that result from breakdowns. By conducting regular maintenance and inspection checks, millwrights ensure the equipment is not just running but operating in the safest, most efficient way possible.

Their role extends beyond the machinery itself; they are fundamental pieces in creating a safer work environment. Their compliance with safety protocols helps prevent accidents and ensure a secure workplace for all involved in the project.

Problem Solvers and Innovators

Construction projects present unique challenges and unpredictable obstacles. Millwrights, with their expertise and problem-solving skills, innovate new solutions that keep projects on track. Whether adapting the machinery to suit specific project needs or solving unexpected issues, their ability to think on their feet is extremely valuable.

A Foundation for Project Success

The success of a project is judged on several factors, including timely completion, staying within budget, and ensuring the safety of all personnel. Millwrights contribute to all these areas, making them integral to the project’s overall success. Their work protects the equipment and machine tools and safeguards the project against delays and complications.

Overall, millwrights are much more than just mechanics or technicians. They are critical players in the construction process, whose expertise and dedication ensure the smooth execution and completion of the job.

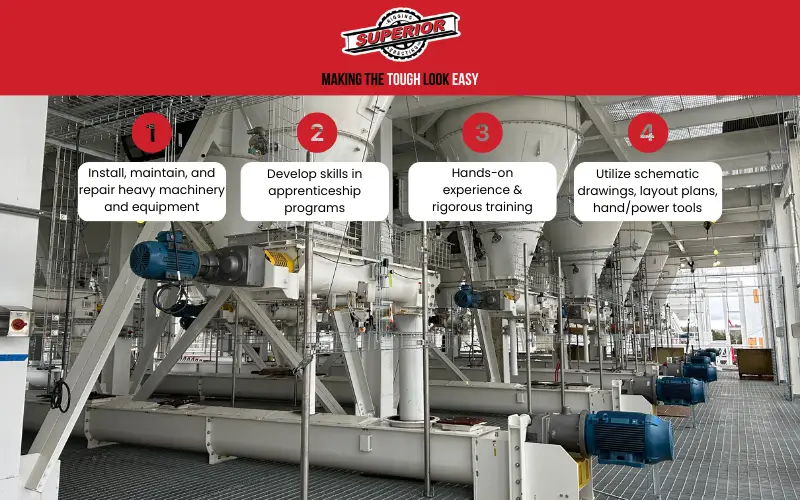

Becoming a Millwright: Apprenticeship and Job Training

Becoming a millwright is stepping into a career that is critical to the infrastructure and development of industries across the world. Enrolling in an apprenticeship program is the first step in millwright education. These programs are normally free and combine classroom instruction with on-the-job training. Over the course of several years, apprentices are exposed to a broad spectrum of skills and knowledge. This ranges from understanding new equipment to mastering safety protocols on construction sites.

The goal of apprenticeship programs is to teach technical knowledge, problem-solving skills, and physical stamina. This ensures that once the apprenticeship is completed, the millwright knows how to operate and maintain the machinery and be able to tackle unforeseen challenges with confidence.

Building a Comprehensive Skill Set

Millwright apprentices must develop a unique skill set to be successful at their job. They should be proficient in reading schematic drawings and layout plans, using hand and power tools, and applying precision instruments to ensure the accurate installation of equipment.

The qualifications don’t stop at technical skills. Effective communication, critical thinking, and teamwork are equally important. Millwrights often work with other tradespeople and must navigate the job sites together.

Continuous Learning and Certification

Continuous education is a large part of a millwright’s career because the field is constantly evolving with new technologies and methods. Many people pursue additional certifications in specific areas of machinery operation or even leadership and management to enhance their capabilities. This commitment to lifelong learning keeps millwrights at the forefront of the industry.

A Career of Impact

Becoming a millwright is choosing a career that makes a tangible difference. Aside from the satisfaction of solving mechanical challenges, millwrights have the benefits of a highly rewarding profession. These benefits include competitive / higher salaries, opportunities for advancement, and the chance to work in different locations and unique industries.

Superior Rigging & Erecting Co’s Millwrighting Services

At Superior Rigging & Erecting Co., we have a team of highly skilled and experienced millwrights that form the backbone of our operations. Our millwrights work closely with our team of crane operators, riggers, and other professionals in complex tasks like machinery installation, alignment, and maintenance. We realize the importance of having a competent millwright team for the success, safety, and efficiency of a project.

The success we have achieved over the past 70 years aligns with the incredible work of our millwrights. Their expertise, dedication, and teamwork ensure that each project is executed with precision and care. At SRE, we cover the needs of your project no matter the size or location. We serve the industrial and manufacturing industry, food processing and beverage, mission-critical, and many more! Reach out to SRE today to request a quote for our top-quality millwright services.

Resources:

- Superior Rigging & Erecting Co. https://superiorrigging.com/