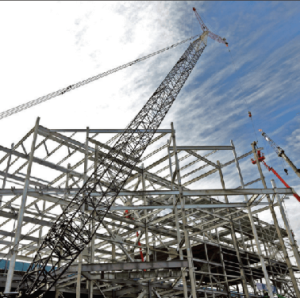

In the construction industry, using heavy equipment like cranes, bulldozers, and forklifts is essential for completing projects efficiently and effectively. However, the operation of this machinery comes with safety risks that can lead to accidents and injuries if not properly managed.

Heavy equipment, fundamental to construction work, supports tasks that would otherwise be impossible due to their size and complexity. The operation of these machines requires an understanding of the potential hazards involved, including unexpected start-up and breakdown, and the risk of serious injuries.

The Risks Associated with Heavy Construction Equipment

Construction sites are busy environments where the potential for accidents rises with the use of heavy machinery. Recognizing and addressing these risks is essential for creating a safe workplace.

Common Heavy Equipment Hazards

A few common hazards of using heavy equipment include equipment failure, equipment overturns, blind spots, falling loads, and traffic collisions, to name a few. To prevent these hazards from occurring, operators must use effective communication skills and focus on the task at hand.

Mitigating Risks Through Awareness and Action

Taking a proactive approach to safety is necessary to reduce the likelihood of construction accidents. Workers and operators must be trained to recognize the hazards associated with handling heavy equipment and take action to prevent accidents.

Safety measures include maintaining a clean and organized worksite, implementing and following comprehensive safety protocols for equipment operation, and ensuring that all workers are aware of the danger zones.

Essential Safety Tips and Protocols

Implementing safety guidelines are vital steps that protect every individual on the construction site. Key safety measures for heavy equipment operation include:

- Personal Protective Equipment (PPE): Ensuring that all workers wear the right safety equipment, such as hard hats, safety glasses, high-visibility clothing, and steel-toed boots, is a must. PPE is the first line of defense against injuries.

- Adherence to Safety Regulations: Compliance with occupational safety standards like those set by OSHA is a requirement. These rules provide a framework for safe operation practices and the use of heavy equipment.

- Proper Training: Operators must receive comprehensive training on the specific equipment they will be using. This includes understanding its controls, maintenance, and the potential hazards it poses.

Implementing Best Practices on the Construction Site

- Routine Inspections: Regular checks of equipment condition are done to identify potential mechanical issues before they lead to accidents. This includes checking for leaks, ensuring all controls are working correctly, and verifying safety features are in place.

- Effective Communication: Clear communication among all team members is vital to safety. This includes the use of hand signals, radios, and other communication tools to ensure that everyone is aware of ongoing operations and movements around the site.

- Protocols for Entering and Exiting: The three-point rule for climbing on and off equipment helps prevent falls, one of the most common accidents on construction sites. Operators should always have two hands and one foot, or two feet and one hand, in contact with the equipment when getting on or off.

- Use of Seat Belts: Just like in any vehicle, seat belts are important. They keep the operator securely in the seat in the event of a tip-over or collision.

These safety protocols and best practices are the pillars of heavy equipment safety. But it’s not just about following rules; it’s about building a culture of safety where every worker is committed to implementing these practices.

The Role of Operators and On-Site Workers in Ensuring Safety

The foundation of a safe construction site is not just the implementation of safety protocols but also the people who bring these practices to life. Heavy equipment operators are on the frontline when it comes to safety. They make an impact on the job site through their comprehensive training and equipment checks.

Beyond basic operation, operators should undergo extensive training on safety, emergency response procedures, and dealing with specific hazards related to their equipment. This training ensures they have the necessary skills to handle the machinery safely and react appropriately in unexpected situations. Operators must also perform pre-operation inspections to make sure the equipment is in good working condition.

Responsibility of All Construction Workers

While operators have a direct impact through controlling the equipment, all workers share the responsibility for maintaining a safe environment. As mentioned, effective communication and teamwork are essential, especially in signaling and alerting others about ongoing operations. Every worker, regardless of their role, must also wear appropriate PPE and stay clear of designated danger zones.

Creating a Culture of Safety

The key to safety on construction sites is creating a culture where safety is everyone’s priority. This culture is built on continuous education and the empowerment to act. Ongoing training sessions keep safety top of mind and ensure that all team members know the latest safety rules and regulations. Workers should also feel empowered to report unsafe conditions or practices without the fear of punishment. A proactive approach is key to preventing accidents before they happen.

Technology Enhancing Safety in the Construction Industry

As the construction industry evolves, so does the approach to safety on job sites.

- Advanced Equipment with Safety Features: Modern equipment now comes with enhanced safety features, such as improved visibility, automatic warning systems on load limits, and stability controls. These features assist operators in operating the vehicle smoothly and avoiding accidents.

- Wearable Technology: Helmets and vests with modern technology can monitor workers’ health signs and alert them to potential hazards in their environments. This technology can help to prevent heatstroke, detect falls, and make sure workers aren’t exposed to dangerous levels of noise.

- Drones and Robotics: Drones are used to conduct site inspections and monitor work areas, while robotics can perform tasks in environments considered too risky for humans, such as demolition and heavy lifting in unstable areas.

Superior Rigging & Erecting Co.’s Commitment to Safety

With over 70 years of experience in the construction industry, we have consistently prioritized the safety of workers on every project. All our highly skilled operators have at least an OSHA 10 and NCCCO certification, ensuring they are experts in safety practices. We understand that safety is an evolving challenge that requires ongoing education and adaptation to new technologies and practices. Our team is committed to making sure every construction site is a safe environment for all workers, paving the way for more efficient and safer project execution. Reach out to SRE today to learn more about our compliance with safety standards and how we continue to “Make the Tough Look Easy.”

Resources:

- Occupational Safety and Health Administration. https://www.osha.gov/

- Superior Rigging. https://superiorrigging.com/