A gantry is a type of overhead crane designed with freestanding legs. These legs are mounted on wheels and allow the crane to traverse along a track or rail system. This mobility is what sets gantries apart from other cranes. It enables them to operate in various environments, from tight indoor spaces to expansive outdoor settings.

Gantries are adaptable tools and are valuable for indoor sites where the equipment is challenging to navigate around. Their design allows for seamless maneuvering of equipment in complex layouts, making them ideal for lifting and handling art pieces and industrial equipment. In outdoor applications, gantries are used for managing tasks such as unloading cargo from ships. This flexibility makes gantry cranes essential across diverse industries including manufacturing, shipping, construction, and logistics.

At Superior Rigging & Erecting Co., gantries play an integral role in our rigging processes. We specialize in using gantries for tasks that require more precision and careful handling for heavy-duty operations. Our decades of experience in this industry allow us to provide solutions that are effective and tailored to the unique needs of each project. Our use of gantries ensures efficiency and safety, demonstrating our commitment to delivering top-tier service in every endeavor. This blog post will focus on the advantages of using a gantry, its features, stand-out components, and how SRE uses these cranes in action.

Two Types of Gantries

Gantries are important pieces of equipment with various advantages. Their design and functionality offer a blend of strength, versatility, and precision, making them ideal for various applications. There are different types of gantries used in construction projects, each meeting the specific needs of the client. Some of the main types include the portable gantry crane, full gantry crane, bridge crane, and semi-gantry crane.

- Portable Gantry Crane: These cranes, known for their mobility and adaptability, are best suited for light to medium lifting. They are perfect for indoor and outdoor settings where a permanent installation is not needed.

- Semi-Gantry Crane: These gantries combine the design of an overhead bridge crane with a full gantry. These cranes have higher flexibility, with one side supported by an elevated runway and the other side traveling on a ground rail.

SRE’s Gantry Offerings

At Superior Rigging & Erecting Co., gantries are a huge advantage to our rigging operations. These machines allow us to be competitive in the jobs we complete for customers. Many customers have projects requiring heavy lifting in a tight space, and this is where our team comes in. Our expertise in operating the right gantry for each job sets us apart, ensuring efficiency and safety in each project.

Our range of offerings includes:

- Spanco Gantry: These gantries are known for their reliability and versatility, and are typically used for outdoor applications and heavy-lifting projects.

- 1-ton Aluminum Gantry Crane: Aluminum gantries are lightweight and durable tools, offering mobility and ease of use.

- 2-ton and 5-ton Aluminum Gantries: These aluminum gantries are ideal for medium-duty tasks, combining strength with flexibility.

- 3-ton Steel Gantry: These are a sturdy option for more rigorous tasks.

- 2-ton Gantry: This is a versatile gantry that balances capacity and maneuverability for a wide range of applications.

- 400-ton Gantry (with Operator): This is a hydraulic crane that lifts 400 tons of weight. These are used for the most challenging projects and require a skilled professional for operation.

Components and Features of Gantries

As we explore more about gantries, it’s important to understand their components, the building blocks that determine the crane’s functionality, efficiency, and safety. A gantry includes several key components:

- Single and Double Girder: The main difference between girders is the crane’s load capacity and duration of work. Single girders are typically used for light to moderate loads and shorter periods of work, while double girder gantry cranes are best suited for medium to heavy loads and higher levels of work.

- Support Columns: These are the vertical structures that support the girders and the entire crane. They lift and transport heavy loads, providing stability for the crane to operate safely.

- Horizontal Beam: This component, often called the bridge, spans the width of the crane and is the main support for the load.

- Hoist Trolley: The hoist lifts and lowers the load, while the trolley moves the hoist along the horizontal beam. These components work together for precise positioning of the load.

- Wheels: Wheels provide mobility to the crane, allowing it to run across the track or rail system in a straight line.

Safety Features

Safety is the most important factor in the operation of gantries. Modern cranes have several safety features to ensure smooth operations. Overload protection is one feature that prevents the lifting of loads beyond the crane’s capacity. Emergency stop systems are a feature allowing for immediate shutdown in hazardous situations. Anti-collision devices help prevent accidental collisions with other cranes or nearby structures. Lastly, warning alarms alert personnel during crane operations, ensuring everyone is aware of the crane’s movement. At SRE, we make these safety features a top priority in all our operations, ensuring a secure environment for our team and clients.

Materials Used in Construction

The construction materials used with a gantry influence its performance and suitability for different environments. Two common materials used are stainless steel and aluminum. Stainless steel is known for its strength and corrosion resistance. This material is often used in heavy-duty construction projects, especially those operating in harsh conditions. On the other hand, aluminum is ideal for lighter gantries. Aluminum offers portability and flexibility, making it the best choice for indoor and outdoor tasks. With an understanding of the gantry structure and features, one appreciates its capabilities. SRE ensures that every aspect of a gantry’s operation aligns with the highest standards of efficiency and safety.

How Gantry Cranes Work – From Load to Lift

Gantries are more than just towering structures in industrial environments; they are dynamic machines that transform the concept of lifting and moving heavy loads.

The operation of an adjustable gantry crane begins with the accurate positioning of the crane over the load. This process is crucial because it determines the efficiency and safety of the lift. Once the crane is in position, the hoist lowers and hooks to the load with secure rigging. The load’s weight, height, and dimensions are important factors at this stage. They ensure the crane operates smoothly and the load is balanced correctly.

The crane operator then uses a hook device to lift and balance the load. The trolley maneuvers it along the horizontal beam, transporting it to its destination. This movement requires an understanding of the crane’s mechanics and an awareness of the surrounding environment, ensuring a clear path to avoid any obstacles.

The Crane Operator’s Role and Safety Precautions

Crane operators are responsible for controlling the crane and ensuring the safety of the load, the crane, and the workers. This responsibility requires adhering to all safety precautions, such as verifying the load capacity, ensuring correct rigging practices, and communicating with ground personnel. Additional pieces of equipment are used to support the operator’s efforts. These include emergency stop systems and warning alarms, ensuring the smooth operation of the crane.

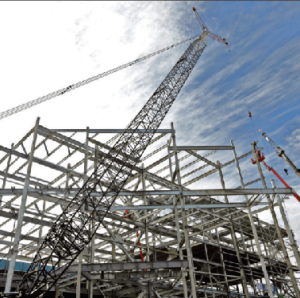

Gantries in Action

In the construction industry, gantries are solutions that bring efficiency and safety to complex tasks. When considering a gantry crane for your next project, it’s essential to consider various factors to ensure the crane fits into your specific needs.

Understanding the work area is crucial. The size, shape, and conditions of the space where the gantry operates determine the type of crane suitable for the task. Whether it’s a tight indoor space or an open outdoor area, it’s essential to select a crane with the right dimensions and mobility. Another important factor is the adjustable height of the crane. Different projects require different lifting heights and load sizes. From small loads to large, heavy materials, the crane must be capable of lifting the item safely and effectively.

Superior Rigging and Erecting Co.’s Reliable Services

At SRE, we demonstrate our expertise through various projects across the Southeast. One notable example of our gantries is with Aspen Aerogels. We transported nine air handling units, each weighing 12,000 lbs, into a facility with restricted access. We faced several challenges with handling this project, but it demonstrated our ability to adapt to challenging constraints. We utilized our gantry system to successfully deliver on this complex rigging project.

We understand the importance of choosing and operating the right gantry for your project, which is why our team is here to assist you in selecting the right equipment for your needs. It’s important to note that we don’t offer bare rentals. Our gantries include experienced operators, ensuring each task is completed with the utmost safety and expertise. This approach not only guarantees the efficient completion of your project but also ensures adherence to quality and safety standards. If you’re searching for a premium gantry service provider, contact SRE today to learn more!

Resources:

- Spanco. https://www.spanco.com/product_category/gantry-cranes/

- Superior Rigging & Erecting Co. https://superiorrigging.com/