What Does a Rigger Do?

In short, a rigger uses his or her knowledge of the trade to safely move or relocate a product while utilizing appropriate equipment and methods.

There are hundreds of ways to move a product, but a rigger is trained to understand physics such as distribution of weight, sling capacities, sling angles and configurations, in order to move the product safely and without damage.

In this blog we dive deeper into how a rigger performs work and what you should look for in a qualified and competent rigger.

Important Factors & Techniques a Rigger Needs to Know

Skating & Jacking

Machine skates are a piece of equipment used to move heavy products. They are made up of a count of wheels contingent to the weight of the load they will support. The wheels on the skates are made of steel, nylon or poly. Choosing the correct skate depends on the ground surface needs or protection. Competent riggers are trained on how to choose and utilize skates to move heavy equipment safely.

A rigger must be able to properly position the correct machine skates under the load in a way that is secure and ensures stability. From there, every move must be made with precision. The slightest bump could derail the load and cause serious damage or injury.

Jacks and forklifts are used to lift equipment so that it can be safely placed on machine skates. This technique is especially useful when space is restricted or when the movement is a short distance. Skating and jacking allow the product to be safely placed in its final location.

This technique is crucial to moving and setting large, modularized products, which is primarily how manufactures produce equipment today.

Understanding Sling Angles

The sling angle is where the sling meets the load.

The angle directly impacts the lifting capacity. Sling angles are important because as the horizontal sling angle decreases, the greater the tension on the slings. Employees can be greatly injured, and your product can have significant damage if the tension is too high.

Let’s look at the sling angles for a rigging plan designed to lift an item that weighs 900lbs with two slings.

A person without proper rigging training may think that two slings, rated at 500lbs each, would be appropriate. The sling angle will affect the sling’s capacity positively or negatively.

First, the rigger needs to ensure the slings capacity exceeds the items weight.

Next, the rigger should calculate the tension factor. The hitch impacts this step. A rigger could use a choker hitch, vertical hitch or vertical basket hitch.

Finally, as the horizontal sling angle decreases, the sling tension increases.

The standard recommended sling angle for the rigging industry is 60 – 90˚. It’s possible to fall under 60˚ if you have limited head room or have a unique lifting solution. Any lift under 30˚ is not recommended but if performed requires a critical lift plan.

Reduction Factors

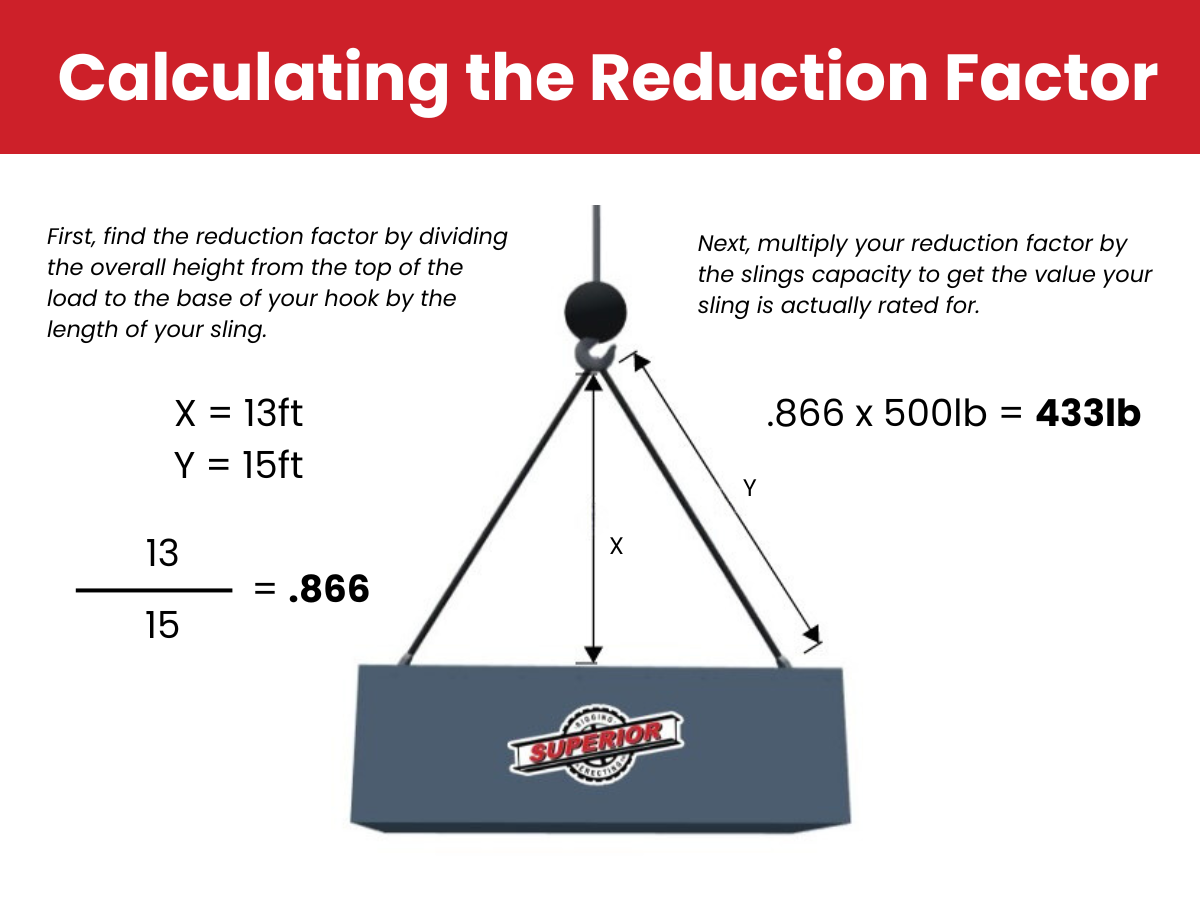

In the above case, let’s consider that the rigger is utilizing slings in a vertical configuration. Each sling is rated for 500lbs and 15ft long.

To calculate the reduction factor, you must divide the overall height from the top of your load to the base of your hook by the length of your sling. In the illustration below the height is shown as X and the sling length is shown as Y.

Let’s say the height is 13ft and the sling length is 15ft for this scenario. 13 divided by 15 equals .866. So, your reduction factor is .866.

If you take your reduction factor and multiply it by the capacity of the sling, which was 500lbs, we now see our capacity is only 433lbs per sling. This puts us at a total lifting capacity of 866 lbs, which is not appropriate for our 900lb load.

The reduction factor always needs to be evaluated to make the decision whether to form a new rigging plan. This could include adding a spreader bar or using a sling with a greater lifting capacity.

In this case, the best decision would be to use a different sling with a higher rated capacity.

Critical Lift Plans

According to OSHA, a lift becomes critical if it meets one of the following criteria:

- Exceeds 75% of the rated capacity of the crane or derrick.

- Requires the use of more than one crane or derrick.

Your rigging personnel should be well-trained to recognize situations where a critical lift plan is necessary. The rigger collaborates with the crane operator to complete the requisite paperwork and oversee the critical lift.

Crane and rigging companies hold different standards when it comes to critical lift plans. At Superior, we mandate a critical lift plan under the following circumstances:

- Dual cranes are needed for the pick.

- The load exceeds 75% of the crane’s capacity.

- Other heightened safety factors come into play.

Riggers should try to avoid critical lifts if possible. Sometimes due to limited headroom or extremely heavy products these lifts are necessary and can be completed safely with the proper training.

Selecting a Qualified Rigger

According to OSHA, a qualified person is:

“A person who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge or training and experience, successfully demonstrated the ability to solve/resolve problems related to the subject matter, the work, or the project.”

It is up to each employer to decide what qualifications, certifications and trainings amount to a qualified rigger. There are several nationally accredited organizations that provide training, standards and certifications. A few include:

- NCCCO – National Commission for the Certification of Crane Operators

- ANSI – The American National Standards Institute

- ASME – The American Society of Mechanical Engineers

- OSHA – Occupational Safety and Health Administration

Be sure to ask the company or rigger you plan to work with about their qualifications. Anyone can claim to be a rigger, but this is not an area of work you want to take a gamble. It’s most likely that you don’t want someone responsible for your product if they aren’t certified by an accredited organization.

Riggers can earn these qualifications through their employer, trade school or a union apprenticeship.

At Superior, all riggers are union trained and hold a minimum OSHA-30 safety training, signalperson and flagging training and OSHA approved rigging course.

Safety

Proper safety training is important for every person on a job site. You should be sure the rigger responsible for your load has general safety training and rigging specific safety training. At Superior we don’t just value safety because we have to, but because the lives of our employees and the value of our client’s product is of the upmost importance.

Rigging safety includes sling inspections to ensure rigging is intact and capable of lifting, proper signaling, flagging and fall protection.

Sling inspections should be done every day prior to hooking to an item. Rigging slings are full of smaller fibers that allow for loads to be lifted. Even the slightest tear can cause the sling to malfunction and a product could be dropped.

There are inspection guidelines to go by when inspecting slings. The main one is that there are red fibers mixed in. If the outer coating is compromised and the red fibers are exposed, then the sling should be taken out of service.

There are many more safety standards a rigger must follow. The above are just a few examples.

Types of Equipment Riggers Use

It can take a combination of rigging equipment to move one product. Riggers are trained to understand how to properly use all equipment and execute the plan put in place by the rigging operations team. At any point if a product cannot be moved safely with the equipment on site, they should stop work and develop a new plan.

Common types of equipment riggers use are:

- Slings

- Chain Falls

- Skates

- Tugger Systems

- Gantries

- Bolts

- Hydraulic Jacking Systems

- Air and pneumatic systems

- Spreader bars

- Shackles

- Chokers

- Forklifts

- Cranes

Teamwork on the Job Site

A rigger must know how to work with a team. They should never be rigging alone.

Riggers work closely with customers, operations, sales, crane operators, project managers and various subcontractors and general contractors.

A good rigging team will have operations spend most of the time pre-planning so the rigging crew can meet expectations and deliver results on the job site.

At Superior, we take pride that our riggers are not only highly skilled, competent and qualified, but they are customer focused during every interaction and decision. They take into consideration the customer’s success, project timeline and value of product before any lift.

This article has been reviewed by industry expert Justin Sheffield, Superior Rigging & Erecting Co. Rigging Operations manager, on 5/15/2024.

Resources:

- Occupational Safety and Health Administration. https://www.osha.gov/

- Superior Rigging & Erecting Co. https://superiorrigging.com/

- Brittany Self