How Are Cranes Transported?

Transporting a crane might seem like a straightforward task, but in reality, it’s extremely intricate. Every construction project, whether it’s lifting heavy equipment for a data center or a new stadium build, relies on the timely and safe arrival of these engineering monsters. Understanding the nuances of crane transportation not only ensures project success but also safeguards workers and the public. But how exactly are these cranes moved from one place to another?

Whether it’s the mobile crane you see whizzing down the highway or the boom truck that appeared overnight at a busy construction site, we’re diving deep into the world of crane transportation.

Types of Cranes and Their Transportation Needs

The vast world of cranes is as diverse as it is intricate. A crane is just another towering structure at a construction site, but dive a little deeper, and you’ll realize each crane type is a marvel of engineering, tailored for specific tasks and environments.

Overview of Cranes

- Mobile cranes: Versatile and often used when quick setups are required, our mobile cranes include the all-terrain truck crane, boom trucks, and hydraulic truck cranes. They’re very common, especially when there are heavy loads or heavy equipment to be lifted. We also have carry deck cranes and rough terrain cranes, which can maneuver a job site with ease, but must be transported to the site.

- Crawler Crane: These are track-based cranes, excellent for stable lifting capacity, especially on soft terrains. Their unique track system requires specific transportation considerations.

- Overhead Crane: Typically found in manufacturing units and warehouses, overhead cranes, or gantry cranes, run on elevated tracks. They’re usually built on-site, but transporting their components is a meticulous task.

Understanding Crane Transport Methods

Every crane is unique in its design and function, so the approach to transporting each crane varies.

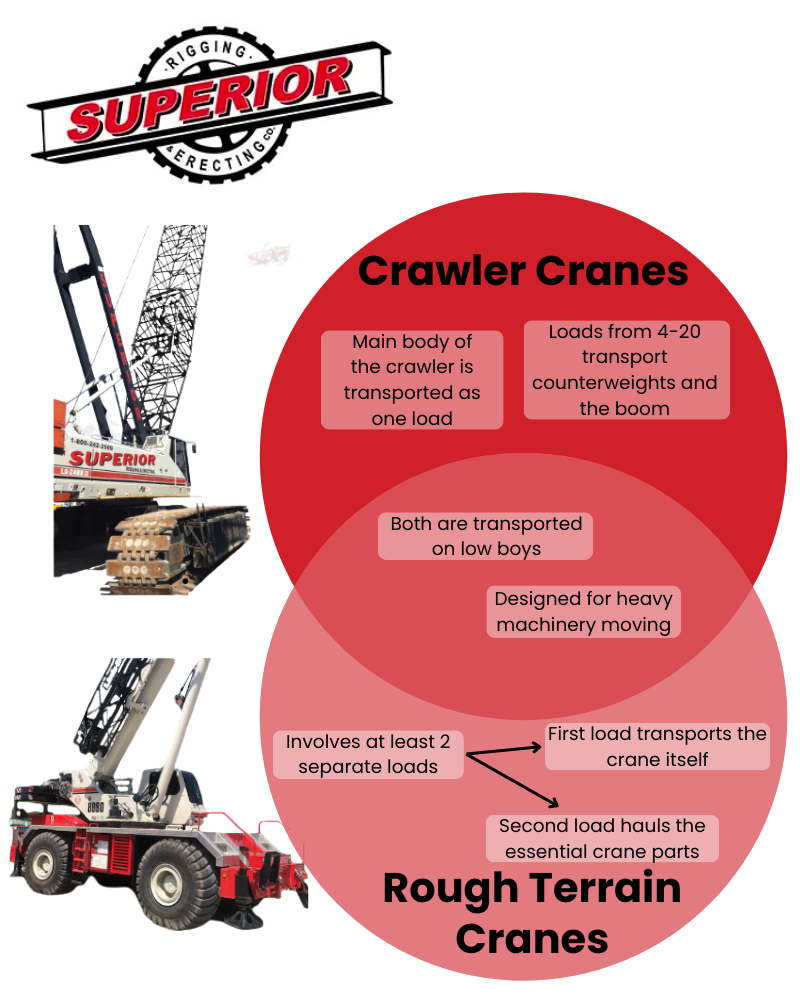

Similarities: Crawler Cranes and Rough Terrain Cranes

These are often transported on low boys, a type of trailer designed for heavy machinery. Depending on the crane’s weight, components called stingers (extra axles) are added. For example, smaller cranes weighing 90,000 lbs can fit on a single tractor-trailer, cranes weighing around 148,000 lbs require a setup with 7 axles, considering the maximum load, tractor, and trailer, and cranes tipping the scales at 160,000 lbs require 8 axles and are categorized as a super load.

Rough Terrains (RT)

Typically, transporting RTs involves at least two separate loads. The first load transports the RT crane itself using a lowboy. The second load, depending on the crane’s tonnage, is responsible for hauling essential crane parts, like counterweights and outrigger boxes.

Crawlers

The transportation method for crawler cranes varies significantly. The main body of the crawler is transported as one load on a lowboy. Additional loads, ranging from 4 to 20, transport important crane parts such as counterweights and the boom. For perspective, a 100t Crawler requires around four loads, whereas an LR 1300 would need a minimum of 17 loads.

Mobile Cranes

The procedure for other mobile cranes is more straightforward. The crane is driven to the site directly, and essential parts like counterweights and luffer parts, depending on the crane’s tonnage, are transported separately. For example, just the counterweights for an LTM 1300 6.2 can account for 5 loads. Some cranes are also self-erecting, adding another layer of convenience.

At SRE, we are experts on the intricacies of each crane type. Our deep knowledge ensures that whether it’s a new crane for a landmark project or a refurbished crane for a smaller endeavor, transportation is always seamless, safe, and efficient.

The Crane Transportation Process

Crane transportation is more than just loading cranes onto a truck and hitting the road. It’s a systematic, calculated process that demands attention to detail at every turn. Ensuring the equipment reaches its final destination intact and on time requires intricate planning, unwavering focus, and innovative engineering.

Preparation

Before a crane ever hits the road, there’s a great deal of preparation work involved:

- Understanding the Crane: Recognizing the specific type of crane is paramount. For instance, a truck-mounted crane might be more mobile compared to an all terrain crane. Knowing the crane’s specifics will dictate the transportation mode and necessary logistics.

- Terrain Assessment: Factors like rough terrain, road width, bridge height, and weight limits are assessed to ensure safe transit to the final destination. For long distances or inaccessible locations, alternative methods might come into play.

- Securing Permits: Crane transport on public roads isn’t a regular day-to-day activity. It requires necessary permits to ensure the safety of all road users. The permits are often specific to the crane’s size, weight, and the transportation vehicle involved.

Modes of Transportation

- Flatbed Trucks: For many cranes, flatbed trucks are a common transport method. These provide stability and ample space, ensuring the crane shipment remains secure throughout the journey.

- Heavy Haul Trucks: For the heaviest crane components or the whole cranes themselves, heavy lift trucks are employed. With their reinforced structure and power, these trucks ensure even the heaviest of loads are transported effortlessly.

Safety Protocols

Safety is a non-negotiable priority in crane transportation. Here’s a glimpse into some vital protocols:

- Escort Vehicles: Larger cranes or their components, when transported, can occupy significant road space. Escort vehicles accompany these transports, ensuring the safety of other road users and assisting in navigation.

- Experienced Crane Operators: The role of a seasoned crane operator cannot be understated. They ensure the crane is appropriately loaded and unloaded from the transport vehicle, minimizing potential damages or risks.

- Load Balancing: Ensuring the crane’s weight is evenly distributed on the transport vehicle is crucial. Misbalances can lead to vehicular malfunctions, delays, or accidents.

We have mastered this art of crane transportation at Superior Rigging & Erecting Co. Our commitment to safety, combined with our extensive fleet and equipment, ensures every crane is transported to the construction site with the precision and care it deserves.

Superior Rigging’s Excellence in Action

With over 70 years of experience in the United States, we stand as a testament to precision, dedication, and excellence. Our impressive track record speaks volumes, solidifying our position as the subcontractor of choice when perfection is non-negotiable.

We recently completed a project that required our crane rental services. Using our fleet of SRE trucks to build our 350-ton Liebherr crane, we carefully executed the project by transporting all of the equipment to be assembled at the job site. In this project, we implemented our crane rental service with the LTM 1300 6.2 and warehousing service, which assisted in its safe and timely executed completion.

SRE’s expertise, attention to detail, and ability to deliver exceptional results make for successful project execution on every job.

The Future of Crane Transportation

As the demands of the construction industry evolve, so do the methods and technologies used in crane transportation. As we look to the future, SRE will continue to be a leader in the construction industry.

Advanced Technology

The integration of technology into crane transportation is becoming increasingly prevalent. From GPS-enabled route planning that avoids potential obstacles to real-time monitoring systems that track every movement of the equipment, technology ensures safer and more efficient transportation. The use of AI and machine learning can further refine these processes, predicting potential issues before they arise.

Enhanced Safety Protocols

While safety has always been a cornerstone of crane transportation, the future promises even more advanced safety measures. Technology can help in transporting cranes, ensuring they are always in optimal condition to handle the machinery.

Customized Solutions

Every construction project is unique, and so are its requirements. Future crane transportation will lean heavily on customized solutions tailored to specific project needs. Our company, with our vast experience and innovative mindset, will be at the forefront of these solutions, ensuring clients get exactly what they need for their projects.

Contact SRE Today

Contact us today and discover how Superior Rigging and Erecting Co. offers exceptional crane rental services that provide a secure and safe transportation process for your crane rentals.

This article was reviewed for accuracy by the Atlanta Crane Operations Manager, Darrell Clayborne.

Darrell Clayborne is a Certified Crane Operator and operates Superior’s LTM 1300 6.2 crane. With over 20 years of experience at Superior Rigging & Erecting Co., he learned to operate the 200-ton crane, the company’s largest crane at the time. Clayborne has worked on several noteworthy projects at SRE, including erecting and disassembling roller coasters at Six Flags and operating a crane at the Atlanta airport. Clayborne also manages all operators and daily operations for Superior’s expanding equipment fleet.